The environment is a topic close to our hearts. That’s why in 2024 at Metal’s we have decided to expand our Green Mission by initiating two new sustainability projects:

- Measuring the Carbon Footprint to calculate the direct and indirect amount of carbon dioxide (CO2) we emit into the atmosphere daily.

- Developing an LCA tool (Life Cycle Assessment) to understand the environmental impact of Metal’s products throughout their lifecycle.

These ambitious goals were detailed during the presentation of our biennial sustainable development plan, and they will help us offer maximum transparency to our customers and partners regarding our daily activities at Metal’s. In this article, we present the initial results from the Carbon Footprint analysis. The data pertain to the 2023 emissions and are essential for drafting the sustainability plan. Let’s take a look.

Metal’s commitment to sustainability: carbon footprint measurement results

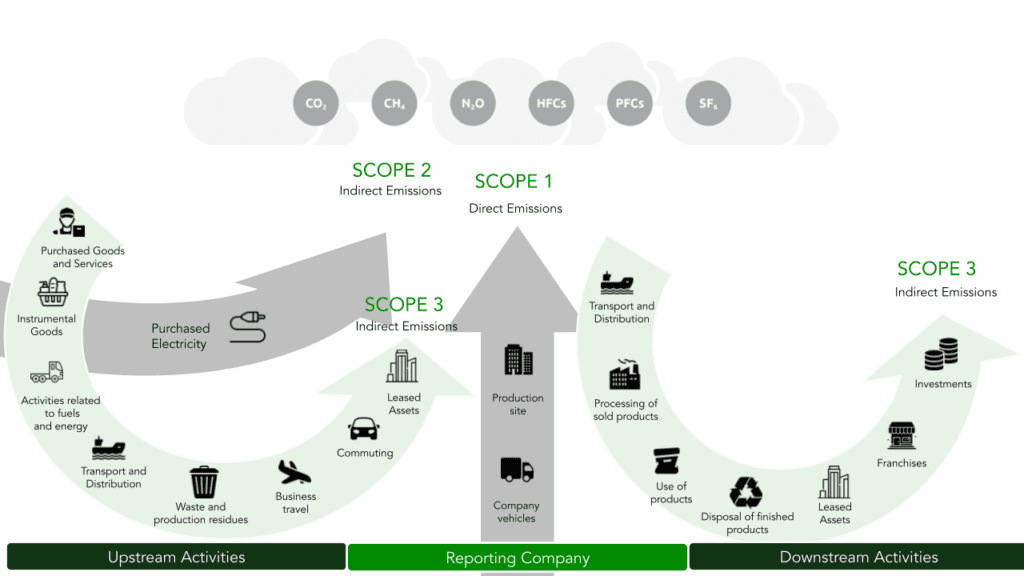

As mentioned, the Carbon Footprint allows us to precisely determine the CO2 emissions of our organization for the year 2023. The calculation is based on the international “Greenhouse Gas Protocol” (GHGP) standard, a recognized standardized method in the “Corporate Standard” that classifies corporate emissions into 3 categories:

- Scope 1: Direct emissions of the company, where all energy bill data or purchase invoices are analyzed to calculate the emissions generated by the organization through production processes and the corporate fleet.

- Scope 2: Indirect emissions where supply contracts and GSE reports (used in photovoltaic systems) are compared to determine emissions originating from an external supplier.

- Scope 3: Includes all other indirect CO2 emission sources related to the company’s business category (including the entire supply chain, goods transportation, business travel, investments).

Let’s examine the data that emerged for Metal’s, one by one.

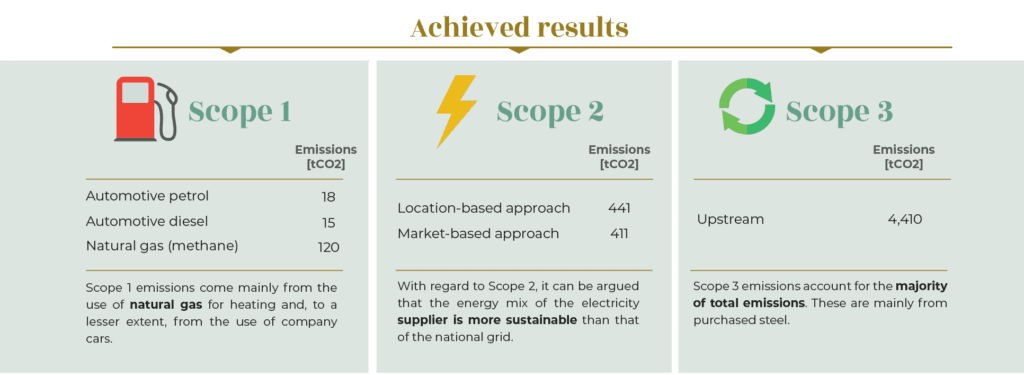

Scope 1: CO2 emissions produced by Metal’s in 2023

The data processing for 2023 revealed that our company emitted 153 tons of CO2. Specifically:

- 120 tons of natural gas

- 18 tons of gasoline for vehicles

- 15 tons of diesel for vehicles

Thus, natural gas, used for heating, contributes 78% to Scope 1 CO2 emissions.

Scope 2: What are the energy consumptions for 2023?

Two different approaches were used to measure the exact value for Scope 2:

- Location-Based Approach: A traditional method considering the emissions of the energy mix of the region where the company is located (the mix can come from renewable sources, as well as nuclear, gas, or coal). This approach correctly represents the energy actually drawn from the grid.

- Market-Based Approach: An alternative that considers only the electricity mix of the company’s supplier, not the regional electric grid mix. This approach accounts for the type of energy purchased, considering the potential purchase of renewable energy.

The first methodology best represents the source of energy drawn from the grid but doesn’t highlight alternative and renewable sources; conversely, the second calculation system showcases the company’s efforts towards a green alternative but isn’t exhaustive regarding the regional sources used. For a more complete result, it is best to consider both.

For Metal’s, the Carbon Footprint analysis for Scope 2 revealed the following 2023 emissions:

- 441 tons of CO2 (Location-Based Approach)

- 411 tons of CO2 (Market-Based Approach)

Scope 3: The purchase of raw materials is impactful

As anticipated, Scope 3 is based on parameters that vary according to the type of company. For Metal’s, the calculations were divided into two macro-categories:

- Upstream Emissions: indirect emissions related to the purchase of goods or services (considering transport, waste, production scraps, leased assets, business travel, and commuting).

- Downstream Emissions: focused on the emissions of sold products (including the transport of finished products to customers, product use, disposal, and investments).

For our organization, the analysis focused on these categories:

- Purchased goods or services

- Capital goods

- Fuel- and energy-related activities

- Upstream transportation and distribution

- Waste and production scraps

- Employee commuting

- Downstream transportation and distribution

From the results, the Upstream category impacts Scope 3 emissions the most (with 99.6%). Here are the detailed percentages:

- Purchased goods or services: 89% (mainly due to the purchase of raw materials like steel and auxiliary materials for producing semi-finished and complex assemblies)

- Upstream transportation and distribution: 6%

- Employee commuting: 3%

- Waste and production scraps, fuel- and energy-related activities: 2%

The Downstream category, considering only the activities of transporting and distributing goods produced by Metal’s to the customer, stands at 0.4%.

Focusing on the analysis of Upstream category data:

- The purchase of raw materials (particularly stainless steel) generated 3010 tons of CO2 (about 82%)

- Packaging and auxiliary materials (such as paper, cardboard, wood for pallets, plastic for packaging, components for assemblies, abrasives for steel brushing, as well as financial, insurance, management services, maintenance, marketing, and outsourced work) impact 3% and 7% of the emissions linked to purchased materials.

What are the total emissions produced by Metal’s in 2023?

Summing up Scope 1, 2, and 3, Metal’s total CO2 emissions for 2023 are 4,716 tons. How should these numbers be interpreted, and what can be done to improve? Here are some plausible hypotheses, subject to technical feasibility evaluations in the sustainability plan to be drafted by the end of the year.

1. Finding New Solutions to Reduce Natural Gas Usage

Analyzing Scope 1 emission values (primarily from natural gas for heating and, to a lesser extent, from company vehicles) reveals that this data is relatively low compared to the total (120 tons of CO2 out of 4,716 tons total, including Scopes 1, 2, and 3).

To improve efficiency, we can consider other ecological heating systems to reduce emissions, such as using electric heat pumps and implementing an electric or hybrid vehicle fleet.

2. Focusing on renewable resources

Scope 2 emissions calculated with the two methods – Location-Based Approach and Market-Based Approach – show that the energy mix of the electricity supplier is already better than that of the national electric grid.

It is still possible to further reduce electricity-related emissions by installing new photovoltaic systems (in addition to those already existing at Metal’s) or purchasing more energy from renewable sources

3. Evaluating the purchase of more sustainable raw materials

For our company, the major source of CO2 emissions is Scope 3. In this case, steel purchase impacts the final percentage. For raw material procurement, Metal’s already relies on European suppliers and other entities sensitive to sustainability (reflecting our Green Mission). Our goal is to reduce the values identified in the Carbon Footprint. To achieve this, we will work on two fronts:

- Collaborating with our suppliers to identify products with the lowest environmental impact.

- Working with our customers to understand the importance of low-emission steel and evaluate their willingness to pay a premium for a sustainable, planet-friendly product.

A final note on waste and production scraps (a category identified within Scope 3). The emission percentage is very low (2%), but this category is strategic. By investing in scrap material, we can produce recycled steel to reduce emissions and increase product circularity.

In conclusion, every action will be decided by the end of the year during the drafting of the sustainability plan.

Want to know more?

If you care about the planet like we do and seek a serious partner already committed to developing sustainable practices, trust Metal’s. We can realize your projects, find out how!