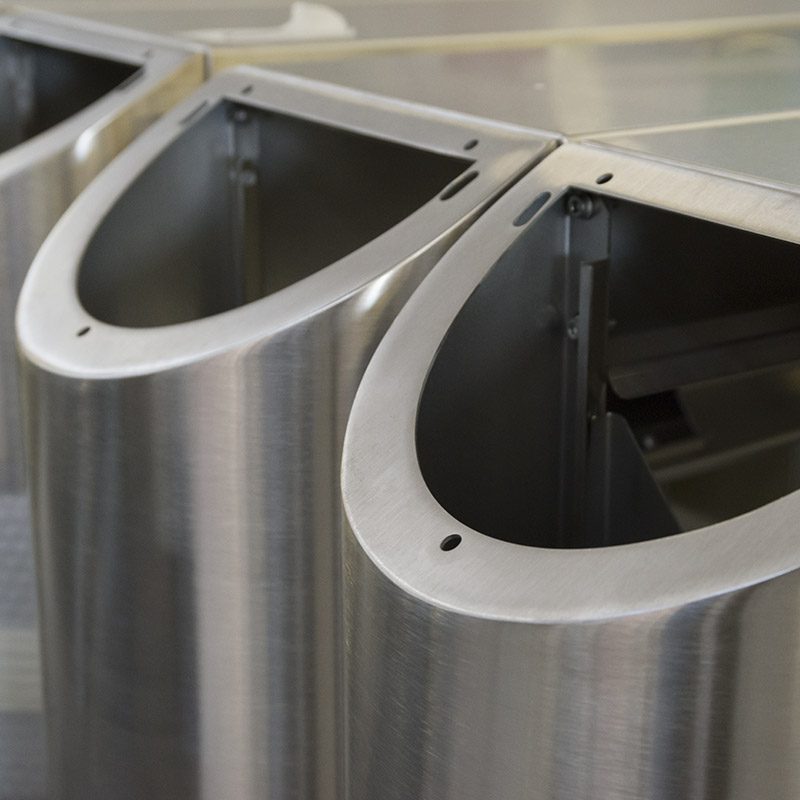

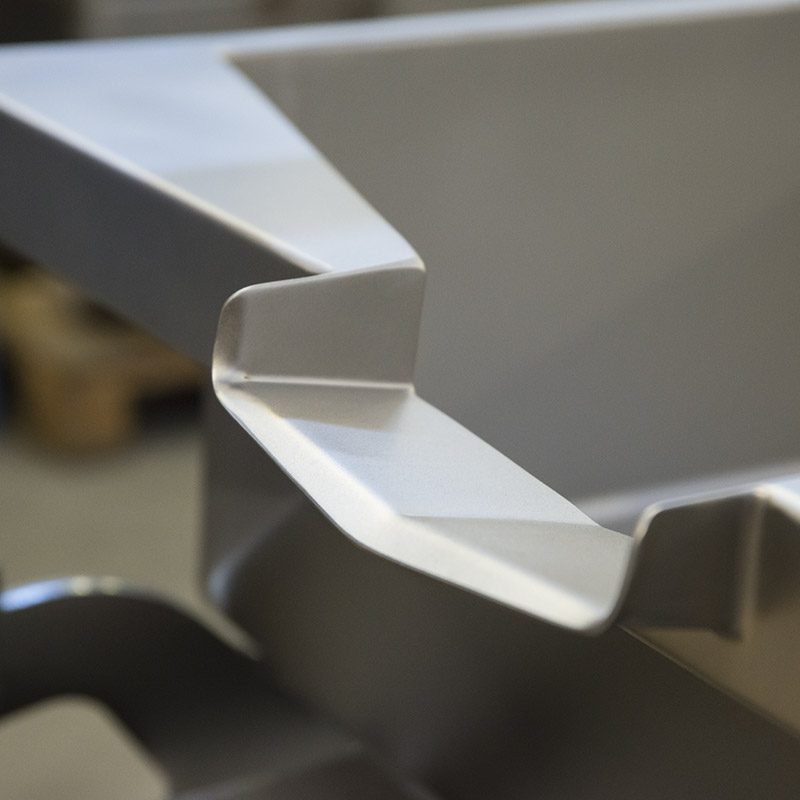

Welding

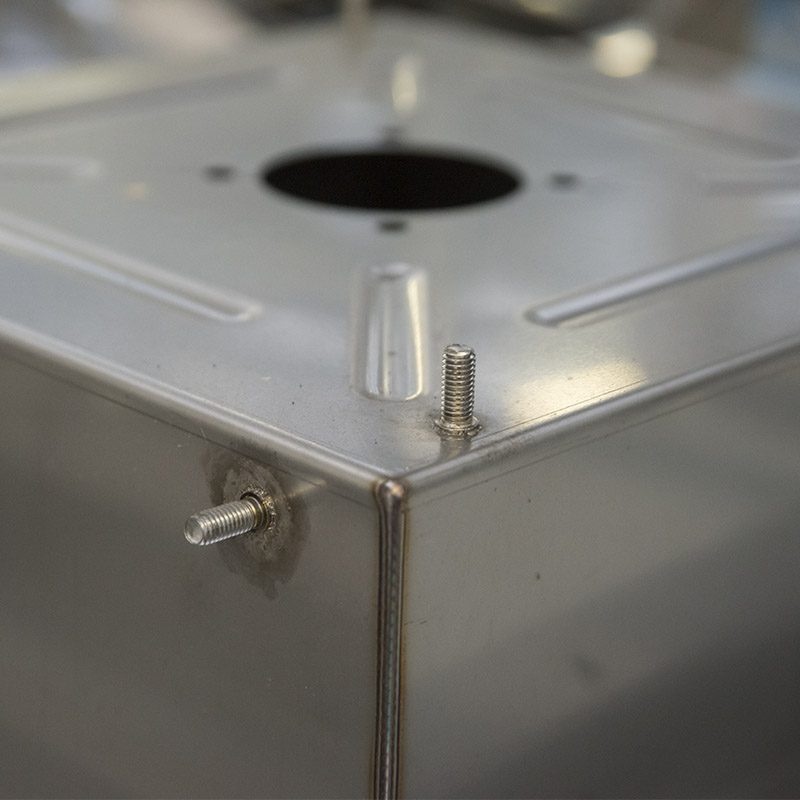

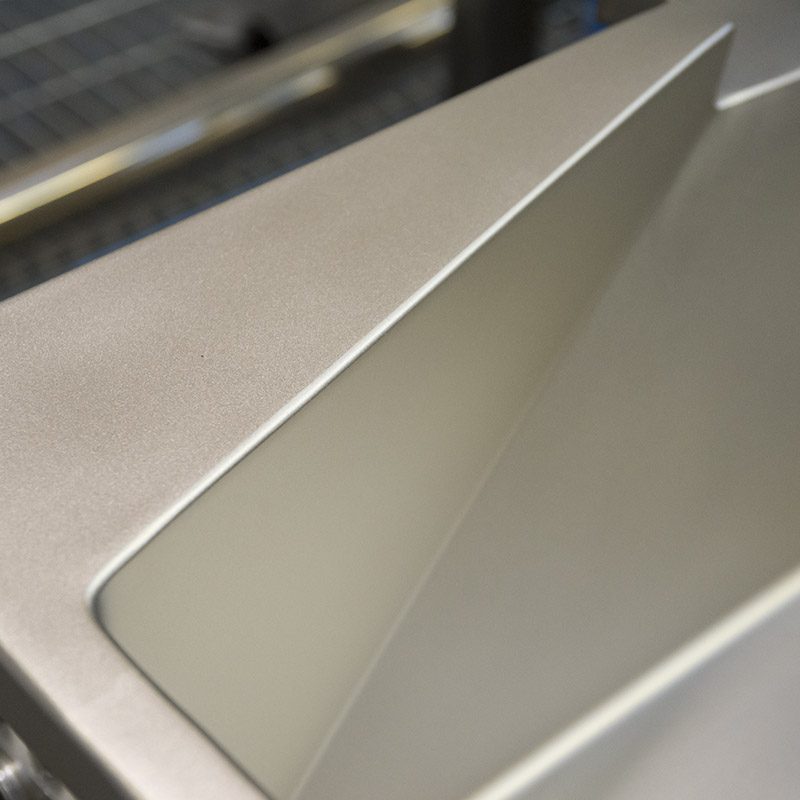

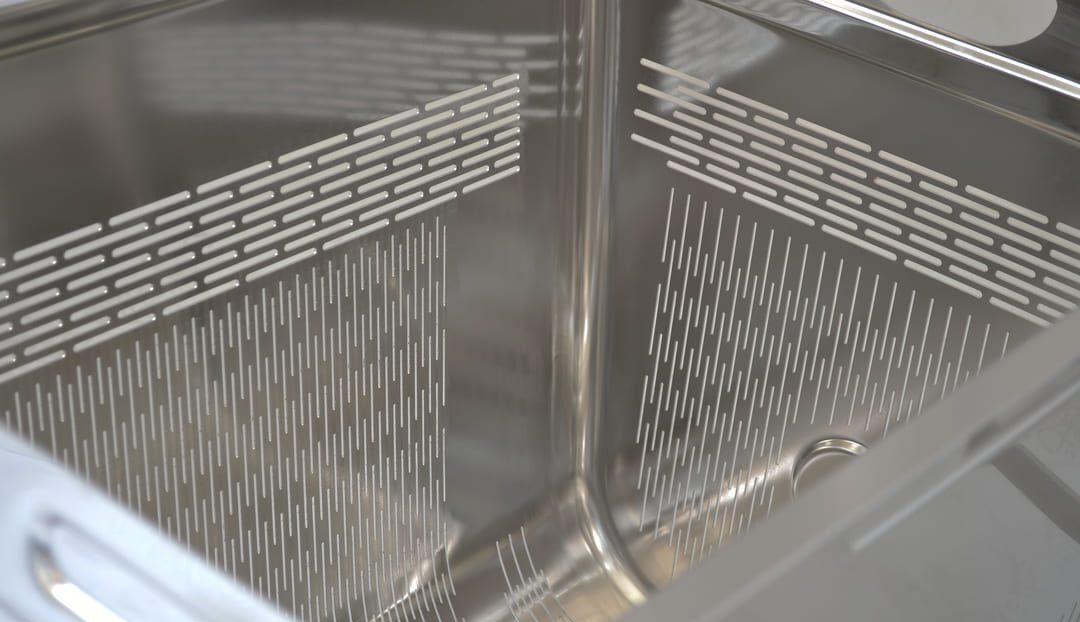

At Metal’s we specialize in the production of semi-finished products and complex assemblies made of stainless steel for medium and large companies operating in different fields, from catering to packaging . Welding is one of the finishing processes of our industrial cycle, and follows the first processes: laser cutting, lasercombined punching, bending and molding..

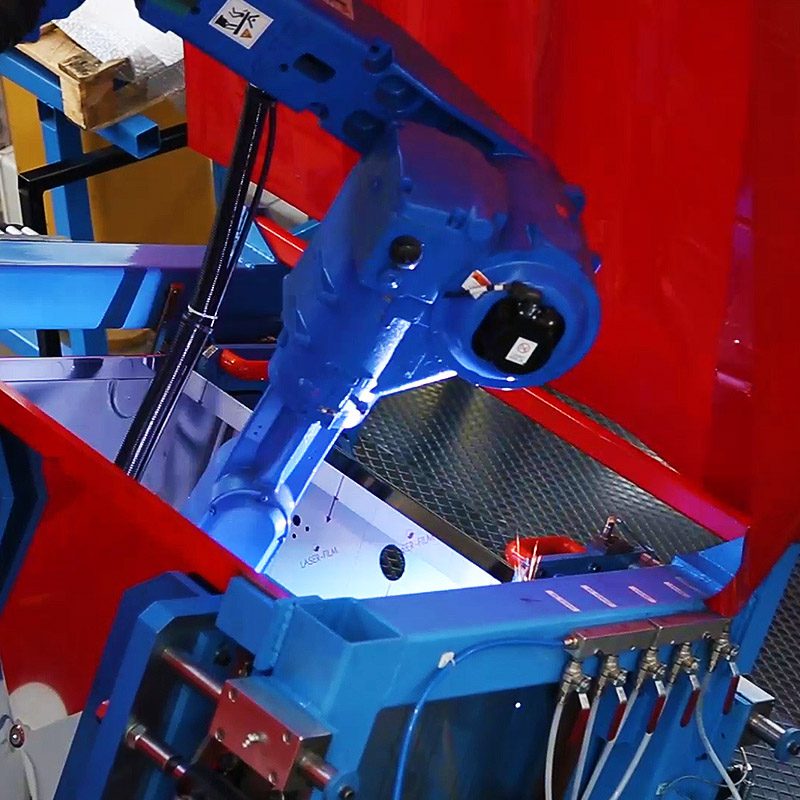

The welding cycle is managed with the help of pulsed TIG and digital MIG systems, which are arranged on robot islands in order to ensure top quality even when processing thin thickness. We are able to perform laser welding processes that allow easy cleaning and surface restoration. Metal’s welders are certified according to UNI EN ISO 9606-1:2017 and meet the the latest regulations’ requirements. Furthermore quality of our welds is certified according to EN ISO 3834-2:2021.