Brushing

At Metal’s we supply semi-finished products and complex assemblies made of stainless steel to medium and large companies operating in different fields . Brushing is one of the finishing processes of our industrial cycle.

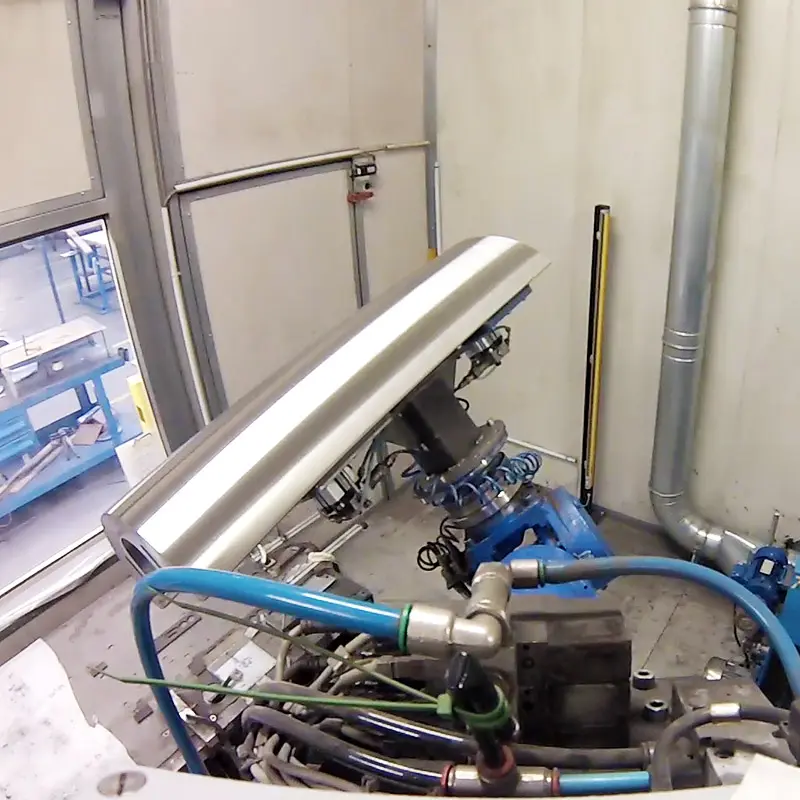

Brushing of semi-finished products and complex assemblies is automated: in our factory we dispose of 3 robotic systems that allow us to obtain top quality roughing, brushing and polishing on a continuous basis. Our machines work 24/7 to ensure speed, precision and the least possible waste.