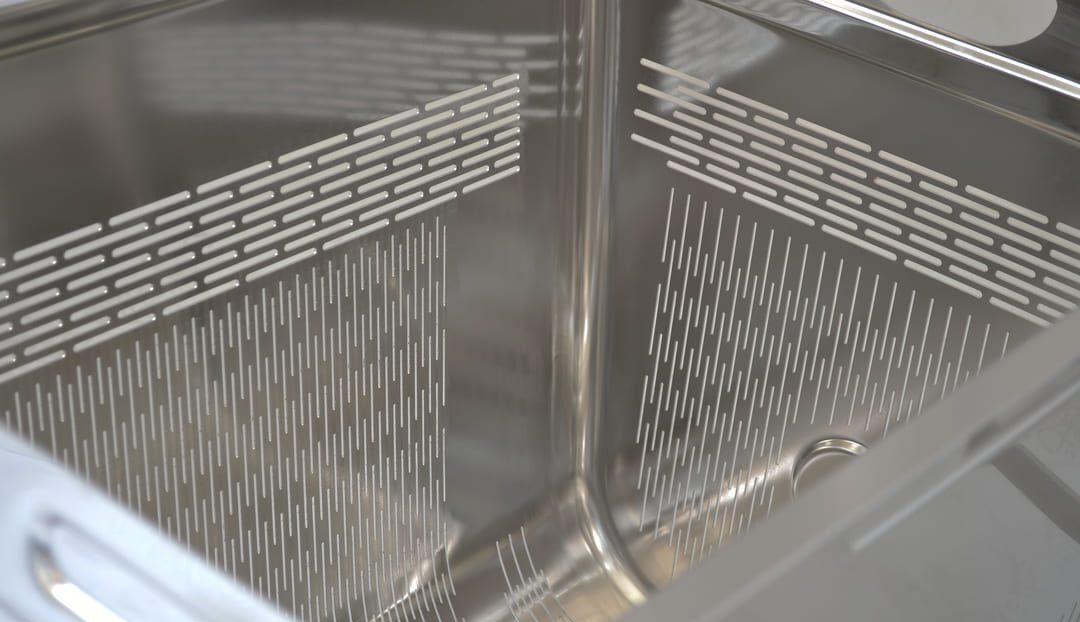

Molds

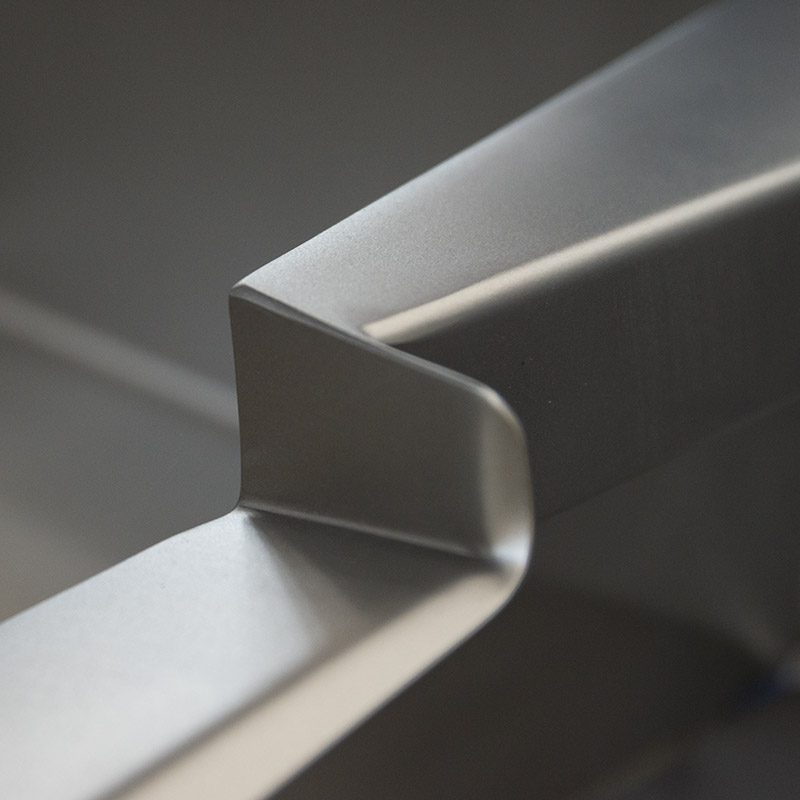

At Metal’s we specialize in the production of semi-finished products and complex assemblies made of stainless steel for medium and large companies in various industries, from catering and packaging up to medical industry. If your project requires the use of molds or equipment, we can make them internally.

We dispose of an entire tooling and mold manufacturing department, with 3-axis CNC milling machine, 1050x600x600 mm worktable and 1000kg load, in order to process the equipment needed for production in the fastest possible way. Aiming at offering you a more and more complete service, our department is also equipped with:

-

parallel lathes with bits 280

-

milling

-

radial drills

-

tangential adjustments

Our technical department designs the molds by using Solidedge design software.

The mold components are made by means of a dedicated program, Mastercam.

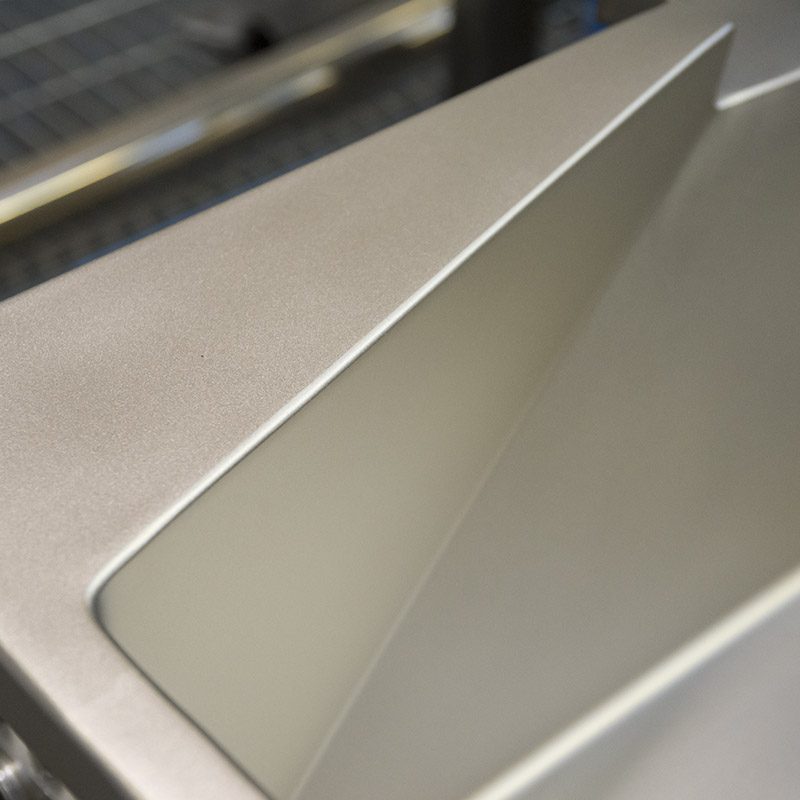

Most of our processes are automatedand our machines work 24/7 to guarantee speed, precision and the least possible waste. If necessary, we can make the finishes in the same cycle in order to obtain top quality and maximum precision.