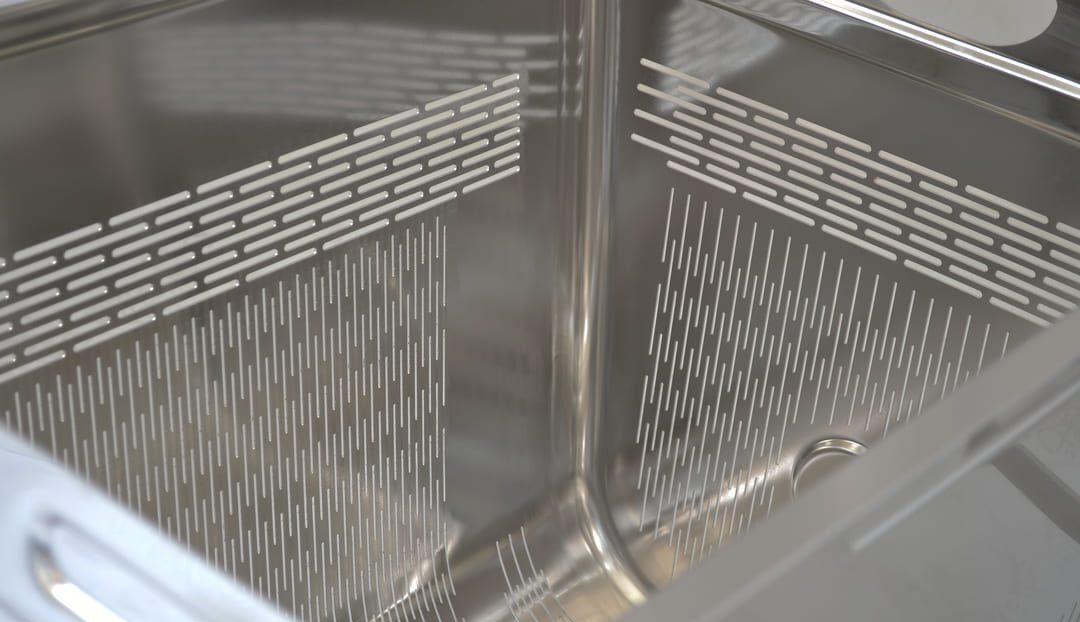

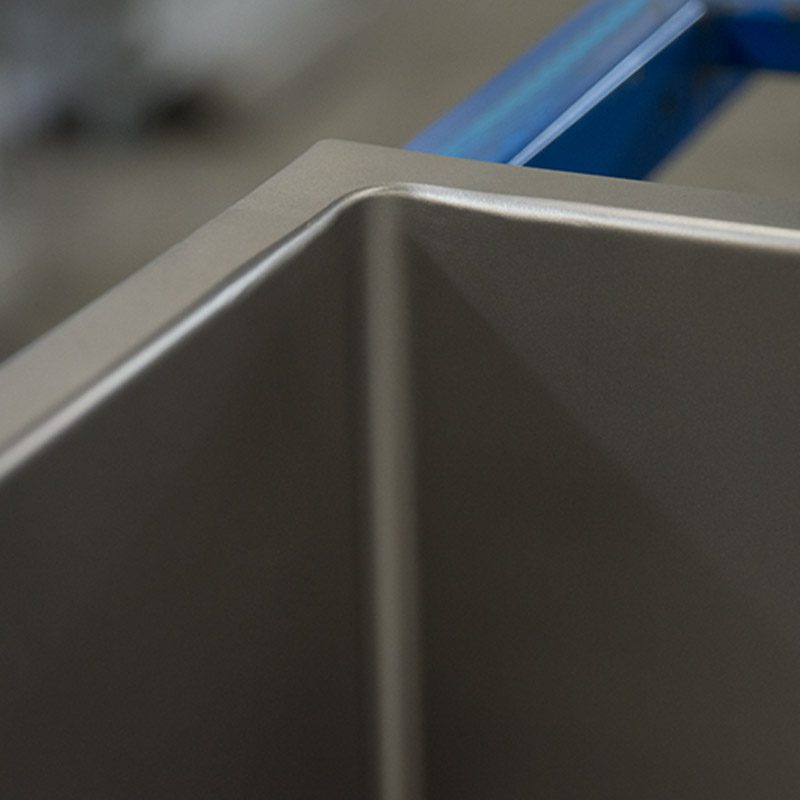

Semi-finished products and components made of stainless steel for machines and accessories for the ice cream making industry

At Metal’s we design and assemble semi-finished products and components made of stainless steel for machines and accessories in the ice cream making industry, paying attention to the smallest detail and in compliance with rigorous safety and functionality standards.

We evaluate and perfect your project in collaboration with you and, through prototyping and engineering, we make semi-finished products even more functional. We manufacture accessories exactly in the quantity you need and when you need them to optimize your warehouse stocks.